Below we evaluate retrievable diffuser systems by reviewing several common primary types of units.

Simple drop-type assembly with a small diameter pipe and “T” section at the bottom. Diffusers are mounted at the “T” section and are installed near one wall of the aeration basin.

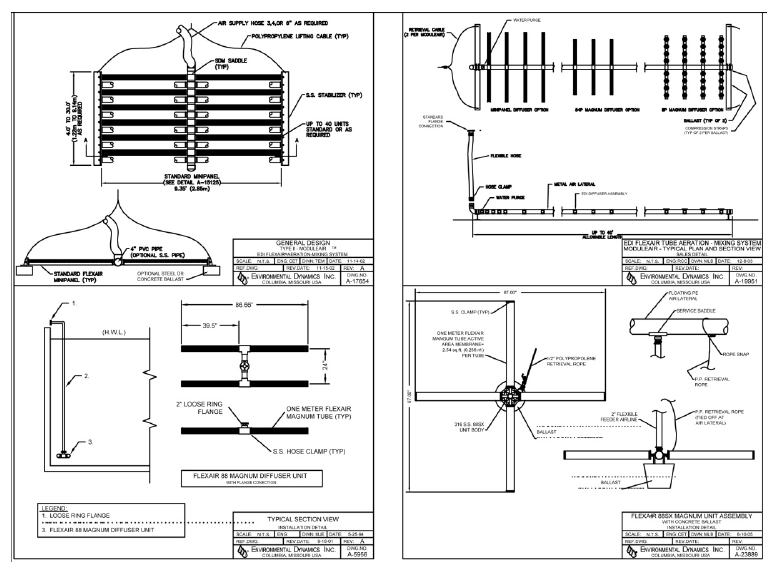

This configuration creates a strong roll mix aeration pattern in the basin size fluid schematics shown in Figure 1.

Figure 1

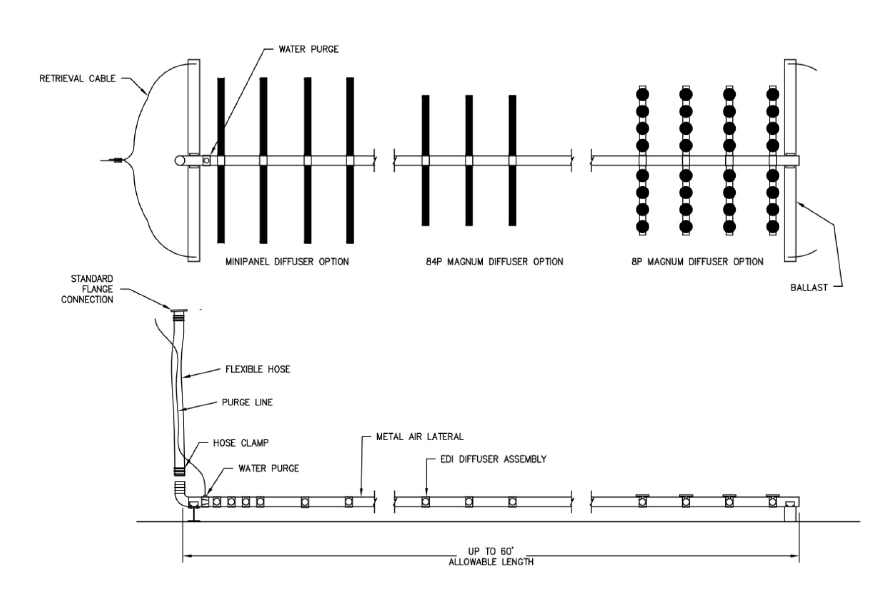

Floating aeration systems that employ characteristics of a floating aeration pipe as an air header on the surface of the liquid.

The air header is fitted with feeder hoses, which deploy the diffusers at the desired elevation in the biological reactor, lagoon, or aeration basin.

There are two primary ways of configuring these systems:

Air flow through the rubber hose is controlled by a valve at the air header, and the diffusers sit on the floor of the basin.

Large activated sludge systems and high intensity aeration systems can employ a retrievable aeration system similar to the EDI ModuleAir™ unit.The ModuleAirTM is a large-diameter PVC or stainless steel pipe fed by a large diameter hose from a metal air header above the liquid surface. This unit is mounted on legs or feet to level the assembly and maintain the assembly and diffusers at the desired elevation. See Figure 2, next page.

To employ this device requires a level and stable floor, such as a concrete floor. Notable characteristics of the system are:

Figure 2

Other specially-designed retrievable diffuser systems are available and configured to distinct project needs.

For customized design requirements, contact Environmental Dynamics International.

By offering easy access for maintenance, the proper use of retrievable aeration mixing systems can significantly increase the ability of diffusers to perform their aeration and mixing duties in water and wastewater systems. These systems can be custom-engineered and applied to each application as required.

The proper selection or application of these products is beyond the scope of this Technical Bulletin. Please contact Environmental Dynamics International for in-depth design considerations.

At EDI Knowledge Center, you'll find invaluable resources and information from our engineers and industry leaders. The EDI Knowledge Center offers readers of our website a deeper exploration and understanding of the latest technologies, operator tips and developments in the wastewater industry. The Knowledge Center is available on the web and in your inbox.

Environmental Dynamics International

5601 Paris Road

Columbia, MO 65202![]() : +1.573.474.9456

: +1.573.474.9456

An Axius Water Company